Neutrosophic Hammer Operator for Assessment of Product Processing Quality Monitoring System in a Machining Line

Keywords:

Hammer Operator; Product Processing Quality Monitoring System; Machining Line; Neutrosophic Sets.Abstract

In modern manufacturing, especially within machining lines, product quality

monitoring has evolved from manual inspections to intelligent, real-time automated systems.

Ensuring consistent product quality while minimizing downtime and defects has become a

critical aspect of competitive production environments. The innovation of digital technologies,

including advanced sensors, artificial intelligence (AI), and Internet of Things (IoT) frameworks,

has significantly improved the ability to track, evaluate, and control processing quality

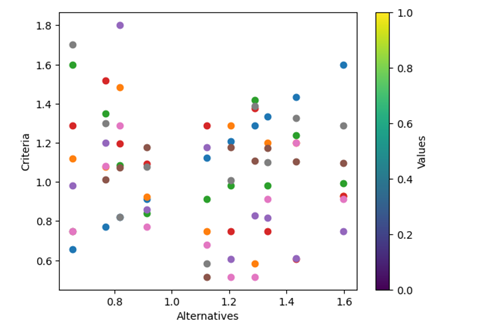

throughout the production lifecycle. This study presents a multi-criteria decision making

(MCDM) comprehensive evaluation of product processing quality monitoring systems in

machining lines by considering multiple performance and integration criteria. By applying a

MCDM evaluation framework, the research aims to determine the most efficient and scalable

solutions adaptable to various production settings. We use the average method to obtain the

criteria weights and the ARLON method to rank alternatives. An application with eight criteria

and ten alternatives is constructed to show the validation of the proposed approach. The

neutrosophic set is used to deal with vague information. Hammer Operator is used to combine

the decision matrices.

Downloads

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Neutrosophic Sets and Systems

This work is licensed under a Creative Commons Attribution 4.0 International License.