Evolution and application of Lean manufacturing in the production industry: advances and trends (2015-2025) through neutrosophic cognitive mapping analysis of critical success factors

Keywords:

Lean Manufacturing, Artificial Intelligence, Production Industry, Neutrosophic Cognitive Mapping, Critical Success Factors, SustainabilityAbstract

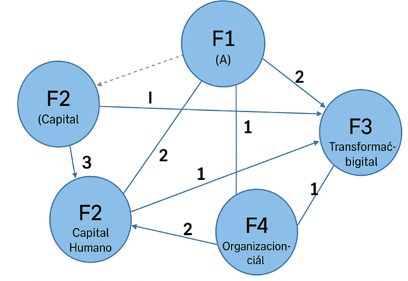

This article examines how Lean manufacturing evolved between 2015 and 2025—a decade marked by rapid technological disruption and the rise of artificial intelligence (AI). The research identifies critical success factors of Lean and analyzes how AI has reshaped its implementation. To address the uncertainty and complexity of expert evaluations, Neutrosophic Cognitive Mapping (NCM) is used as a methodological tool. NCM not only maps interrelated success factors but also incorporates the ambiguity inherent in human and technological assessments. Results show that AI boosts Lean’s effectiveness through predictive analytics and inventory optimization but reveals limitations when workforce training is insufficient. This intersection of Lean and AI provides valuable insights into how their convergence enhances industrial competitiveness, sustainability, and cost efficiency. While prior studies explored Lean's fundamentals, few have focused on its transformation through AI. This research fills that gap, highlighting intelligent automation as a key breakthrough and offering practical guidance for implementation in diverse manufacturing contexts. Ultimately, the study contributes both theoretically and practically, helping industries adopt Lean practices for an AI-driven world.

Downloads

Downloads

Published

License

Copyright (c) 2025 Neutrosophic Sets and Systems

This work is licensed under a Creative Commons Attribution 4.0 International License.